What is the density of tungsten carbide?

The density range of the tungsten carbide is 13.4-15.3g/cm³.

The density fluctuation range of tungsten carbide mainly depends on its composition and preparation process.

The density range of tungsten carbide is roughly between 13.4 and 15.3 grams per cubic centimeter. Specifically, the density of tungsten carbide with different compositions is as follows:

Tungsten-cobalt (YG) tungsten carbide: The main components are tungsten carbide powder (WC powder) and cobalt powder. As the cobalt content increases, the alloy density decreases. For example, the density of tungsten carbide grade YG6 alloy is 14.5-14.9g/cm³, the density of tungsten carbide grade YG15 alloy is 13.9-14.2g/cm³, and the density of tungsten carbide grade YG20 alloy is 13.4-13.7g/cm³.

Tungsten-titanium-cobalt (YT) tungsten carbide: The main components are tungsten carbide powder, titanium carbide powder and cobalt powder. As the titanium carbide content increases, the alloy density decreases. For example, the density of YT5 alloy is 12.5-13.2g/cm³, the density of YT14 alloy is 11.2-12.0g/cm³, and the density of YT15 alloy is 11.0-11.7g/cm³. Tungsten-titanium-tantalum (niobium) (YW) tungsten carbide: The main components are tungsten carbide powder, titanium carbide powder, tantalum carbide powder (or niobium carbide powder) and cobalt powder. As the tungsten carbide content increases, the density of the alloy will increase. For example, the density of YW1 alloy is 12.6-13.5g/cm³, the density of YW2 alloy is 12.4-13.5g/cm³, and the density of YW3 alloy is 12.4-13.3g/cm³. In addition, the density fluctuation range of tungsten carbide is also affected by the preparation process. The density fluctuation of tungsten carbide of the same brand and different batches should not exceed 3%.

In order to let everyone better understand the performance of cemented carbide, I have selected tungsten carbide YG6A grade.

YG6A is a tungsten-cobalt (WC-Co) cemented carbide extensively utilized in the production of cutting tools due to its exceptional hardness, wear resistance, and robust strength. The nomenclature “YG” in YG6A signifies tungsten-cobalt cemented carbide, “6” denotes approximately 6% cobalt (Co) content, and “A” indicates the alloy powder’s grain size at Level 1.

- The chemical composition of YG6A primarily consists of:

Tungsten carbide (WC), serving as the hard phase, offers high hardness and wear resistance.

Cobalt (Co), acting as a binder, enhances the toughness and impact load resistance of the wolfram carbide.

- Performance parameters of YG6A include:

Density of tungsten carbide: Ranging from 14.7 to 15.1 g/cm³.

Tungsten carbide hardness: Typically between 91.0 and 92.8 HRA, indicating remarkable wear resistance.

Bending strength: Capable of reaching 1850 to 2350 N/mm², allowing YG6A to endure substantial cutting forces.

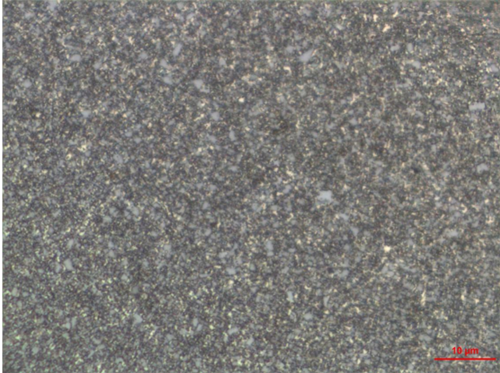

Grain size: Ultrafine grains, usually between 0.6 and 1.0 microns, contribute to improved alloy strength and toughness. The following is a metallographic picture:

Metallographic picture

- YG6A finds diverse applications, primarily in:

- Cutting tools: Suitable for manufacturing various metal cutting tools like drills, milling cutters, and turning tools, particularly effective for processing harder materials.

- Wear-resistant parts: Such as bearings, molds, and valve sealing surfaces.

- Geological exploration: Utilized in the production of drilling tools and wear-resistant components.

- Automotive industry: Applied in manufacturing engine parts and brake system components.

Compared to general high-speed steel (HSS), YG6A boasts superior hardness and wear resistance, enabling higher cutting speeds and feed rates, thus enhancing production efficiency. However, cemented carbide’s price is correspondingly higher.

YG6A is equivalent to ISO: K05.