What is the tungsten carbide hardness?

The tungsten carbide hardness rang is generally 86-94HRA, which is equivalent to 69-83HRC. Different types of tungsten carbide have different hardnesses. For example, cobalt-based alloys and aluminum-based alloys have higher hardness, generally tungsten carbide hardness between HRA82-94.

The tungsten carbide hardness can also maintain a high level at high temperatures. For example, at 900-1000°C, cemented carbide can still maintain high hardness and show excellent wear resistance. In addition, the hardness of wolfram carbide decreases with the change of temperature. For example, at 540°C, the tungsten carbide hardness is 82-87HRA, and at 760°C, the tungsten carbide hardness can still maintain 77-85HRA.

In order to let everyone better understand the performance of tungsten carbide, I have selected wolfram carbide YG8 grade for a detailed explanation. Tungsten carbide grade YG8 is equivalent to the international standard ISO K20.

YG8 tungsten steel, a tungsten-cobalt cemented carbide, is renowned for its exceptional wear resistance, high strength, and impressive impact toughness. Its chemical composition primarily consists of tungsten carbide (WC) at 92% and cobalt (Co) at 8%. Boasting remarkable wear and corrosion resistance, it finds extensive application in mechanical processing, oil drilling, mining engineering, and various other sectors. Below is a detailed introduction to the characteristics, uses, and processing technology of YG8.

Mechanical Properties:

- Tungsten carbide hardness: YG8 tungsten steel exhibits a hardness range of 89~90HRA.

- Bending Strength: 1500 MPa.

- TRS: 2300N/mm².

- Impact Toughness: 2.5-3 J/cm².

- Density: 14.5-14.9 g/cm³.

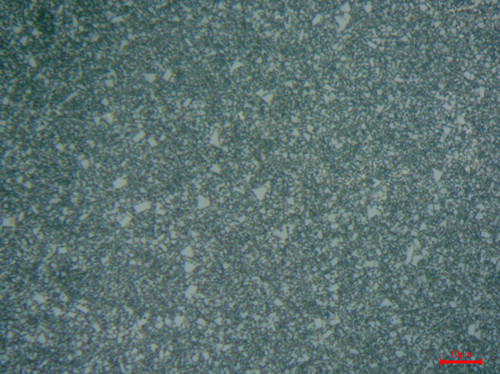

- Grain sizes: See the following is a metallographic picture;

Metallographic picture

Application Areas: Primarily, YG8 cemented carbide’s extraordinary hardness and wear resistance stem from the tungsten-cobalt alloy’s characteristics. Tungsten possesses a high melting point and hardness, while cobalt offers excellent bonding properties, combining to deliver outstanding wear and corrosion resistance. Consequently, YG8 cemented carbide is frequently utilized in the manufacturing of high-wear components such as tools, drill bits, and abrasives.

Secondly, YG8 cemented carbide has a broad scope of applications in mechanical processing. Its high hardness and robust wear resistance enable YG8 alloy tools to perform exceptionally under conditions like high-speed and heavy-load cutting, effectively enhancing processing efficiency and quality.

Additionally, YG8 alloy is prevalent in oil drilling, mining engineering, and mold manufacturing, crafting tools like drill bits and drilling equipment to improve drilling efficiency and reduce costs. For cutting tools, it is suited for high-speed cutting of alloy materials including cast iron, white cast iron, ductile iron, chromium, and nickel stainless steel. In mold manufacturing, it is ideal for drawing dies, stamping dies, and rivet forging dies, particularly for drawing steel and non-ferrous metal wires, and their alloy wires or bars with diameters less than 50mm.

Other Applications: It is used in the production of wire drawing dies, cold brazing dies, and for cold heading, cold punching, and cold pressing dies.

Processing Technology: The production of YG8 cemented carbide involves a relatively intricate process through powder metallurgy. Tungsten powder and cobalt powder are mixed in a precise ratio, with small additions of other alloy elements. These are then pressed, sintered, and processed further to form YG8 cemented carbide blanks. Finally, precision grinding, polishing, and other techniques are employed to craft various specifications of YG8 cemented carbide tools and components.

In summary, YG8 is an exceptional wolfram carbide material characterized by its extremely high hardness and wear resistance. Its widespread use in mechanical processing, oil drilling, mining engineering, and other fields provides robust support and assurance for the development and advancement of related industries. This article aims to offer insight into YG8 cemented carbide and assist professionals within related industries.

Precautions for Use: Given YG8 tungsten steel’s high hardness, the following precautions are recommended:

- Avoid Striking or Throwing: To prevent safety accidents.

- Secure Fixation: Ensure it is securely mounted on the workbench before processing.

- Impact Avoidance: Practice caution during cutting, grinding, and other processing operations.

- Processing Adjustments: For discharge and wire cutting, adjust processing programs to avoid cracking and chipping.

- Welding Considerations: Verify that the processed surface remains intact post-processing.

I hope this article can help you have a better understanding of the tungsten carbide hardness and the performance of wolfram carbide.

Our company is among China’s top ten cemented carbide manufacturers. Should you require cemented carbide products, please contact us.