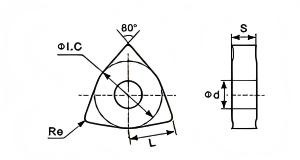

Carbide inserts model;

Different types of carbide inserts:

Carbide turning inserts for lathe:

Carbide round inserts for tuning-lathe:

Carbide grooving inserts for lathe:

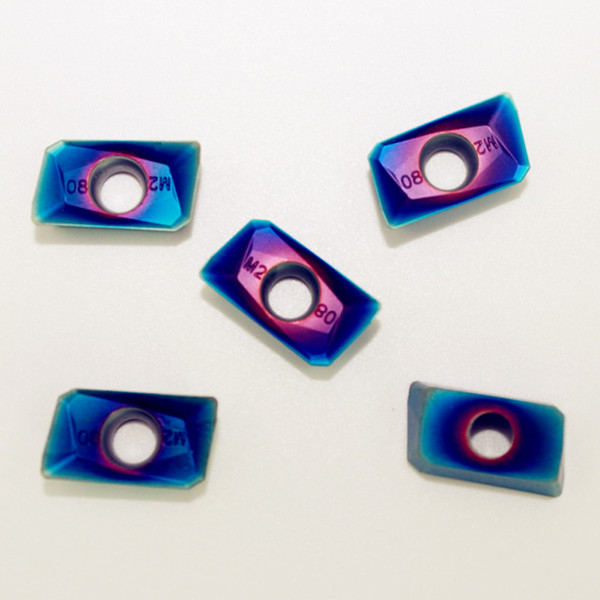

Carbide milling inserts for milling machine:

Metal materials that can be processed:

1. Stainless steel 304/316.

2. Carbon steel, alloy steel and quenched and tempered steel.

3. Cast iron and alloy cast iron.

Support customized packaging.

Please send us inquiries for quotations and free samples for testing: