Applications and characteristics of cemented carbide in the pump industry

Cemented carbide, with its high wear resistance, corrosion resistance and high strength, plays a vital role in the pump industry. This article will explore in depth the application scenarios, specific advantages and contribution of cemented carbide to the improvement of pump performance in the pump industry.

Overview of cemented carbide:

Cemented carbide, also known as metal ceramics, is a composite material made of hard compounds of refractory metals (such as tungsten carbide WC, titanium carbide TiC, etc.) and bonding metals (such as cobalt Co, nickel Ni, etc.) through powder metallurgy. It combines the advantages of metal and ceramic, has high hardness, high strength, high wear resistance, high corrosion resistance and good thermal stability, and is known as the “industrial teeth”.

Application of cemented:

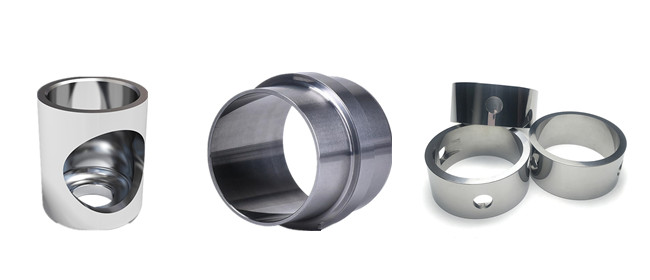

Carbide in the pump industry In the pump industry, cemented carbide is mainly used to manufacture key components of pumps, such as impellers, pump casings, sealing rings, bearings, etc., to improve the wear resistance, corrosion resistance and service life of the pump. The following are several typical application scenarios of cemented carbide in the pump industry:

Impeller: Carbide impellers can withstand the wear caused by high-speed rotation and medium impact, significantly improving the wear resistance and service life of the pump. Carbide impellers are particularly suitable for pumps that transport abrasive media (such as gravel and ore particles).

Pump casing: Carbide pump casings can resist corrosion and erosion of the medium and protect the internal structure of the pump from damage. In pumps that handle corrosive media (such as acids, alkalis, and salts), carbide pump casings can effectively extend the service life of the pump.

Sealing ring: Carbide sealing rings have good wear resistance and corrosion resistance, which can ensure a close fit between the pump shaft and the pump casing to prevent medium leakage. In high-pressure, high-temperature and corrosive media environments, carbide sealing rings can provide reliable sealing performance.

Bearings: Carbide bearings can withstand the wear caused by high loads and high-speed rotation, ensuring the stable operation of the pump. In pumps that need to withstand heavy loads and high-speed rotation, carbide bearings can significantly improve the reliability and service life of the pump.

Characteristics of cemented carbide in the pump industry:

The application of cemented carbide in the pump industry has brought significant performance improvements and advantages, which are mainly reflected in the following aspects:

High wear resistance: Cemented carbide has high hardness and can resist medium wear and erosion, significantly improving the wear resistance and service life of the pump.

High corrosion resistance: Cemented carbide has good corrosion resistance to a variety of corrosive media and can maintain stable performance under harsh working conditions.

High strength: Cemented carbide has high strength and toughness, can withstand the stress caused by high load and high-speed rotation, and ensure the stable operation of the pump.

Good thermal stability: Cemented carbide can maintain stable performance in high temperature environment, is not easy to deform or fail, and is suitable for the transportation of high temperature media.

Long life: Due to the excellent wear resistance, corrosion resistance and high strength characteristics of cemented carbide, it can significantly improve the service life of the pump and reduce the cost of maintenance and replacement.

Application field of cemented carbide pump Cemented carbide pumps are widely used in many fields due to their excellent performance, including but not limited to:

Petrochemical: used to transport corrosive media and high-temperature media such as crude oil, natural gas, acid, alkali, etc.

Metallurgical mines: used to transport abrasive media, such as ore particles, gravel, etc.

Environmental water treatment: used to treat corrosive wastewater and high-concentration wastewater, such as copper-containing wastewater, industrial wastewater, etc.

Power industry: used to transport high-temperature and high-pressure media, such as boiler feed water, condensate, etc.

Conclusion The application of cemented carbide in the pump industry not only improves the wear resistance, corrosion resistance and service life of the pump, but also reduces the cost of maintenance and replacement, making important contributions to the performance improvement and energy conservation and emission reduction of the pump industry. With the continuous advancement of science and technology and the continuous changes in the needs of the pump industry, the application areas and performance advantages of cemented carbide pumps will continue to expand and upgrade, injecting new vitality into the sustainable development of the pump industry.