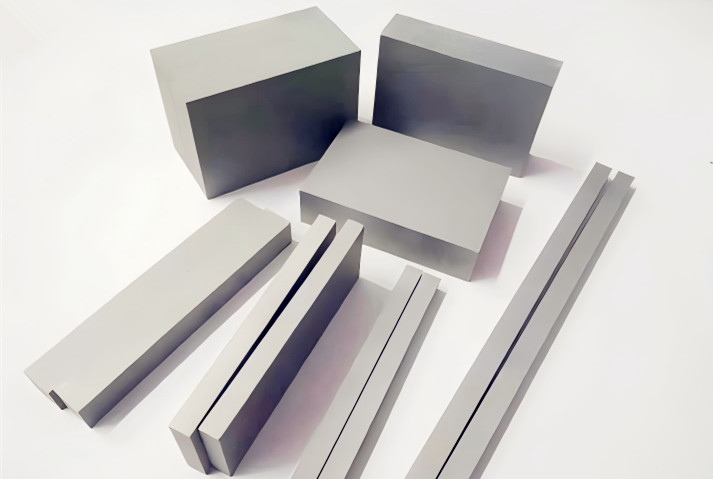

Tungsten steel YG15 for mould industry

YG15 tungsten steel is a type of die steel, specifically tungsten carbide type tungsten steel. Without heat treatment, the hardness inside and outside is uniform. It is used for large-scale production, has excellent strength and toughness, and is suitable for making drawing dies, wear-resistant parts and stamping accessories, and tungsten steel automatic press cores.

YG15 grade performance parameters:

| WC | Co | Grain size (μm) | Hardness(HRA) | Density(g/cm³) | TRS (N/mm²) |

| 85% | 15% | 1.6 | 87 | 14 | 2500 |

The performance characteristics of YG15 tungsten steel are mainly reflected in the following aspects:

- High hardness: The hardness of YG15 tungsten steel can reach HRC65-70, which makes it have high wear resistance when processing high hardness materials.

- High wear resistance: Due to the high content of tungsten and cobalt in YG15 tungsten steel, it has good wear resistance during processing.

- High compressive strength: YG15 tungsten steel has high compressive strength, which makes it have good stability in high pressure and high temperature processing.

- Corrosion resistance: The metal binder in YG15 tungsten steel has good corrosion resistance, which makes it able to resist the erosion of various corrosive media during processing.

The application fields of YG15 tungsten steel are very wide, mainly including the following aspects:

- Mechanical processing: YG15 tungsten steel is widely used in various mechanical processing fields, such as cutting, drilling, boring, planing, etc.

- Mold manufacturing: YG15 tungsten steel has good wear resistance and compressive strength, and can be used to manufacture various molds to improve the service life of the mold.

- Mining drilling: The high wear resistance and corrosion resistance of YG15 tungsten steel make it widely used in the field of mining drilling.

- Aerospace: YG15 tungsten steel also has certain applications in the field of aerospace, such as the manufacture of engine blades, turbine discs and other components.

In order to ensure the quality and performance of YG15 tungsten steel, China has formulated a series of standards for YG15 tungsten steel. These standards include requirements for the chemical composition, physical properties, mechanical properties, heat treatment and other aspects of tungsten steel.

Processing precautions:

- Tungsten steel is prone to cracking and chipping under impact and excessive processing load. Cemented carbide must be firmly fixed on the workbench before processing.

- Tungsten steel has extremely low magnetism, and non-magnetic cemented carbide has no magnetism at all. Please do not use magnets to fix cemented carbide. Please use fixtures to fix it. Please confirm again whether the workpiece is loose before processing. If so, please fix the workpiece until it is firmly fixed.