How is tungsten carbide made

Tungsten carbide (WC) is a material with extremely high hardness, which is often used to make industrial products such as cutting tools, molds and abrasives. The production process of tungsten carbide mainly includes steps such as raw material preparation, mixing, drying, sintering and post-processing. How is tungsten carbide made ? I will explain in detail through the following process.

1. Material preparation:

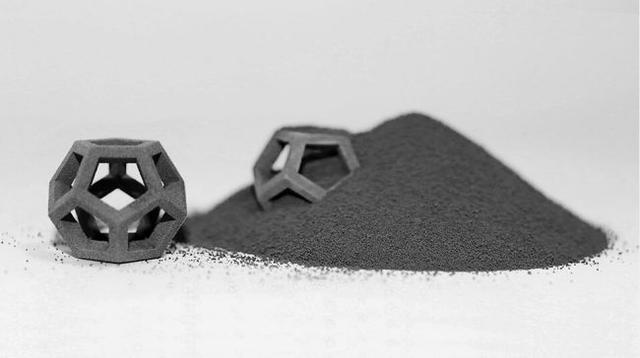

First, raw material preparation is the first step in the production of tungsten carbide. Generally, powder metallurgy is used to mix tungsten powder and carbon powder in a certain proportion. Tungsten powder is prepared by ore dressing, refining and crushing with tungsten ore as raw material. Carbon powder is prepared by carbonization reaction with graphite as raw material.

2.Powder mixing:

Then, mixing is to mix tungsten powder and carbon powder according to a certain formula ratio. There are two common ways of mixing. One is mechanical mixing, which is to put tungsten powder and carbon powder into a ball mill for mixing so that tungsten powder and carbon powder are evenly distributed; the other is wet mixing, which is to mix tungsten powder and carbon powder with organic complexing agent respectively, and then mix them.

3.Pressing and molding:

Put the mixed tungsten carbon powder into a mold for pressing and molding. During the pressing process, the pressure and time need to be controlled to ensure that the density and shape of the molded parts meet the requirements. The next step is the drying process, in which the mixed tungsten carbon powder is dried at high temperature to remove residual moisture. Drying can be carried out in an oven or a drying chamber, and the temperature and time are controlled according to the specific process requirements.

4.Sintering:

Sintering is one of the key steps in the production of tungsten carbide. The dried tungsten carbon powder is sintered into blocks by heating at high temperature. The sintering temperature is generally between 1400℃ and 1600℃, and it needs to be maintained for a certain period of time so that the tungsten powder and carbon powder react chemically to form tungsten carbide.

5.Post-processing:

After sintering, post-processing is also required, mainly including heat treatment and mechanical processing. Heat treatment is to anneal or over-burn the sintered body to adjust the material properties and reduce internal stress. Mechanical processing is to cut, turn, grind and other processes on the heat-treated tungsten carbide to make it a final product that meets the requirements.

In general, the production process of tungsten carbide includes several main steps such as raw material preparation, mixing, drying, sintering and post-processing. By reasonably controlling the parameters and process requirements of these steps, tungsten carbide materials with stable quality can be obtained.