How to polish tungsten carbide and cemented carbide ?

Overview:

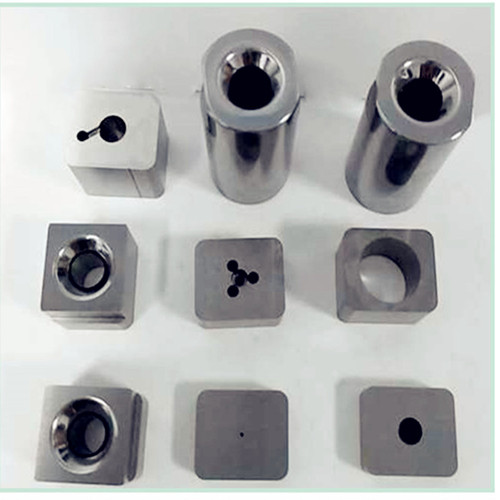

How to polish tungsten carbide and cemented carbide? Tungsten carbide and cemented carbide are materials with high hardness, high wear resistance and high strength, which is widely used in mechanical processing, mold manufacturing, mining engineering and other fields. However, the processing and polishing of cemented carbide is relatively difficult, especially for achieving mirror polishing. This article will introduce several commonly used cemented carbide and wolfram carbide mirror polishing methods.

1.Mechanical polishing:

Mechanical polishing is a common and effective method for cemented carbide mirror polishing. This method achieves the purpose of polishing by using mechanical equipment and abrasives. First, select suitable abrasives, such as aluminum oxide sand or corundum, and then fix the abrasives on the grinding tool of the polishing machine. Next, the cemented carbide material to be polished is contacted with the grinding tool, and the abrasive is used to produce a grinding effect on the surface of the material through rotation, friction and pressure, gradually removing the unevenness of the surface of the material until the desired mirror effect is achieved.

The advantages of mechanical polishing are simple operation, high efficiency, and the ability to obtain better surface quality. However, due to the high hardness of cemented carbide, mechanical polishing requires a long time and high energy consumption. In addition, since mechanical polishing easily generates heat, the temperature during the polishing process needs to be controlled to avoid damage to the cemented carbide material.

2.Chemical polishing:

Chemical polishing is a method of removing impurities and oxides on the surface of cemented carbide by chemical reaction. Common chemical polishing methods include pickling and electrochemical polishing. Pickling is to immerse the cemented carbide material in an acidic solution to remove surface oxides and impurities through the corrosion of the acid. Electrochemical polishing is to use an external electric field in the electrolyte to cause an electrochemical reaction on the surface of the cemented carbide material to achieve the purpose of polishing.

The advantage of chemical polishing is that it can quickly remove impurities and oxides on the surface of cemented carbide, and can achieve a higher surface flatness and finish. However, this method requires attention to the selection of appropriate polishing liquid and operating conditions to avoid corrosion and damage to the cemented carbide material. At the same time, chemical polishing has a certain pollution risk to the environment, and attention should be paid to the treatment of waste liquid.

3.Grinding and polishing:

Grinding and polishing is a method of improving the surface quality of cemented carbide by grinding and polishing the surface of the material. Common grinding and polishing methods include grinding paper, grinding cloth and grinding liquid. First, select suitable grinding paper or grinding cloth and fix it on the grinding equipment. Then, the cemented carbide material is contacted with abrasive paper or abrasive cloth, and the unevenness on the surface of the material is gradually removed by friction to achieve the polishing effect. The grinding fluid can reduce wear and thermal damage by providing lubrication and cooling during the grinding process.

The advantages of grinding and polishing are simple operation, low cost, and good surface quality. However, this method requires the selection of suitable grinding materials and grinding fluids according to the hardness and surface roughness of the cemented carbide, and the force and speed during the grinding process need to be controlled to avoid excessive wear or thermal damage.

4.Ultrasonic polishing:

Ultrasonic polishing is a method of improving the surface quality of cemented carbide using ultrasonic vibration. This method removes the unevenness and impurities on the surface by immersing the cemented carbide material in an ultrasonic conductive liquid and using the vibration force and impact of the ultrasonic wave. Ultrasonic polishing has the advantages of fast polishing speed, high efficiency, and good surface quality. However, this method requires attention to the selection of appropriate ultrasonic frequency and intensity, and the polishing time needs to be controlled to avoid damage to the cemented carbide material.

Summary:

Mirror polishing of cemented carbide is a key processing technology that can improve the surface quality and finish of cemented carbide. Mechanical polishing, chemical polishing, grinding polishing and ultrasonic polishing are commonly used methods for cemented carbide mirror polishing. Each method has its advantages and disadvantages and scope of application, and the appropriate method needs to be selected according to the specific situation. When performing the polishing operation, it is necessary to pay attention to the selection of appropriate polishing materials, polishing liquids and operating parameters to ensure the ideal polishing effect. Finally, the waste liquid and waste generated during the polishing process of cemented carbide mirrors need to be properly handled to reduce pollution to the environment.