1. Carbide blanks grade:

| Grade | ISO Grade | WC (%) |

Co (%) |

Grain Size (μm) |

Hardness (HRA) |

Density (g/cm³) |

TRS (N/mm²) |

| BU06 | K05-K10 | 94 | 6 | 0.5 | 94 | 14.75 | 3600 |

| YG10X | K20 – K30 | 90 | 10 | 0.8 | 91.5 | 14.35 | 3600 |

| BT15 | K20 – K30 | 90 | 10 | 0.7 | 92.2 | 14.35 | 3900 |

| BT20 | K20 – K30 | 90 | 10 | 0.6 | 92.3 | 14.4 | 4000 |

| BT25 | K30 – K40 | 88 | 12 | 0.6 | 92.5 | 14.1 | 4000 |

| BT25UF | K30 – K40 | 88 | 12 | 0.4 | 92.8 | 14.05 | 4200 |

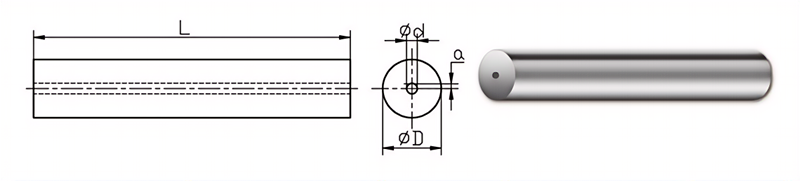

2. Carbide blanks sizes:

|

Type |

D | L (Tol./0,+4) |

d | a | ||

| φ(mm) | Tol. (mm) | d(mm) | Tol. (mm) | |||

| Bφ6xφ1×330 | 6 | +0.30/+0.60 | 330 | 1 | ±0.15 | 0.15 |

| Bφ7xφ1×330 | 7 | +0.30/+0.60 | 330 | 1 | ±0.15 | 0.15 |

| Bφ7xφ1×330 | 8 | +0.30/+0.60 | 330 | 1 | ±0.15 | 0.15 |

| Bφ9xφ1.4×330 | 9 | +0.30/+0.70 | 330 | 1.4 | ±0.15 | 0.2 |

| Bφ10xφ1.4×330 | 10 | +0.30/+0.70 | 330 | 1.4 | ±0.15 | 0.2 |

| Bφ11xφ1.4×330 | 11 | +0.30/+0.70 | 330 | 1.4 | ±0.15 | 0.3 |

| Bφ12xφ1.75×330 | 12 | +0.30/+0.80 | 330 | 1.75 | ±0.15 | 0.3 |

| Bφ13xφ1.75×330 | 13 | +0.30/+0.80 | 330 | 1.75 | ±0.15 | 0.4 |

| Bφ14xφ1.75×330 | 14 | +0.30/+0.80 | 330 | 1.75 | ±0.15 | 0.4 |

| Bφ15xφ2×330 | 15 | +0.40/+0.80 | 330 | 2 | ±0.20 | 0.4 |

| Bφ16xφ2×330 | 16 | +0.40/+0.80 | 330 | 2 | ±0.20 | 0.4 |

| Bφ17xφ2×330 | 17 | +0.40/+0.80 | 330 | 2 | ±0.20 | 0.5 |

| Bφ18xφ2×330 | 18 | +0.40/+0.80 | 330 | 2 | ±0.20 | 0.5 |

| Bφ19xφ2×330 | 19 | +0.40/+0.80 | 330 | 2 | ±0.20 | 0.5 |

| Bφ20xφ2.5×330 | 20 | +0.40/+0.80 | 330 | 2.5 | ±0.25 | 0.5 |

| Bφ22xφ2.5×330 | 22 | +0.40/+0.80 | 330 | 2.5 | ±0.25 | 0.5 |

| Bφ24xφ2.5×330 | 24 | +0.40/+0.80 | 330 | 3 | ±0.25 | 0.5 |

| Bφ25xφ2.5×330 | 25 | +0.40/+0.80 | 330 | 3 | ±0.25 | 0.5 |

Please send us inquiries for quotations and free samples for testing: