Tungsten carbide teeth grade:

| Grade | Co(%) | Density (g/cm³) |

Hardness (HRA) |

TRS (N/mm²) |

Recommended Use |

| BM06 | 6 | 14.95 | 90.3 | 2800 |

DTH Hammers, medium to hard rock |

| BM65 | 6.5 | 14.90 | 90.0 | 3000 | |

| BM08 | 8 | 14.8 | 88.7 | 3200 | |

| B510 | 10 | 14.55 | 88.1 | 3300 |

Roller cone drill bits |

| B411 | 11 | 14.45 | 88.8 | 3200 | |

| B512 | 12 | 14.35 | 87.3 | 3200 | |

| BCK1 | 10 | 14.50 | 85.7 | 2400 |

Road milling bits, mining |

| BCK3-S | 6.5 | 14.85 | 87.5 | 2200 | |

| YH13 | 13 | 14.25 | 88.7 | 3500 |

PDC Substrate |

| YH16 | 16 | 13.90 | 86.6 | 3200 |

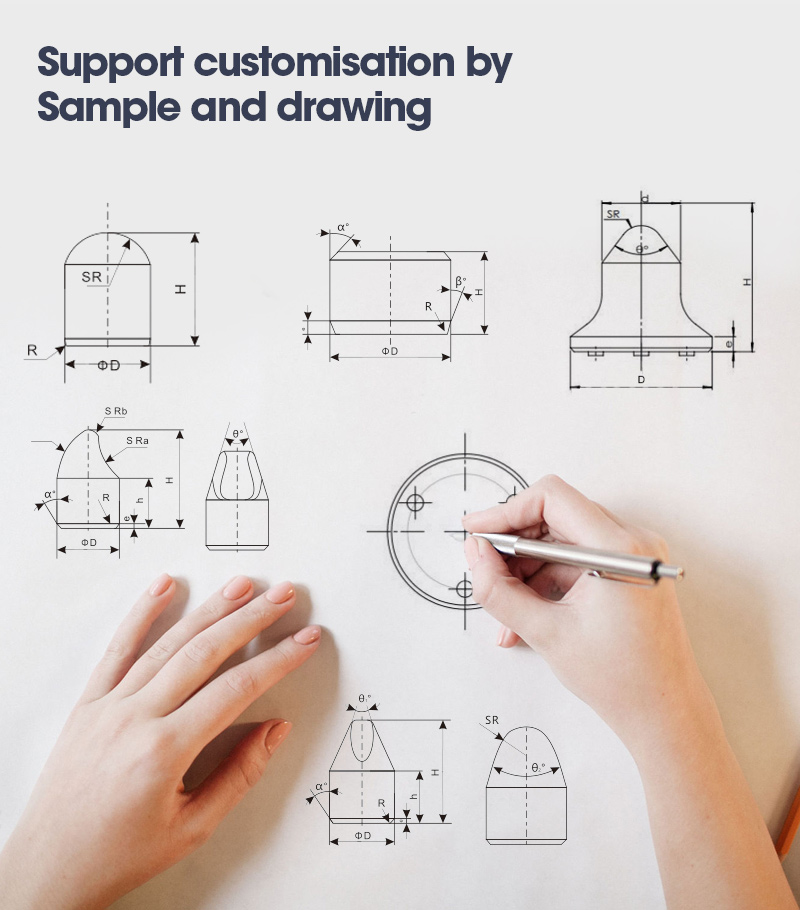

Tungsten carbide teeth drawings:

Please send us inquiries for quotations and free samples for testing: