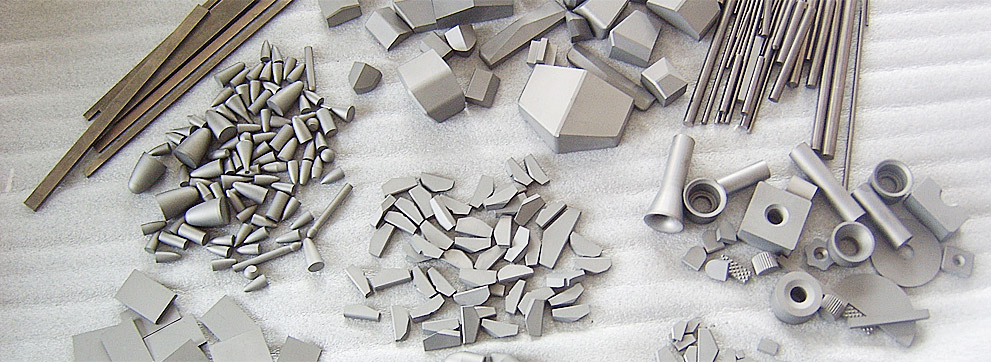

What is cemented carbide?

What is cemented carbide ? What is cemented carbide made of ? Cemented carbide is an alloy made by powder metallurgy with one or more refractory carbide powders (tungsten carbide, titanium carbide, etc.) as the main component, and metal powders (cobalt, nickel, etc.) as binders. It is mainly used to manufacture high-speed cutting tools and hard and tough material cutting tools, as well as cold working molds, measuring tools and high wear-resistant parts that are not affected by impact and vibration.

1. Characteristics of cemented carbide:

⑴ High hardness, wear resistance and red hardness The hardness of cemented carbide can reach 86~93HRA at room temperature, equivalent to 69~81HRC. It can maintain high hardness at 900~1000℃ and has excellent wear resistance. Compared with high-speed tool steel, the cutting speed can be 4~7 times higher, the service life is 5~80 times longer, and hard materials with a hardness of up to 50HRC can be cut.

⑵ High strength and elastic modulus The compressive strength of cemented carbide is as high as 6000MPa, and the elastic modulus is (4~7)×105MPa, both of which are higher than high-speed steel. But its bending strength is low, generally 1000 ~ 3000MPa

⑶ Good corrosion resistance and oxidation resistance Generally, it can resist atmospheric, acid, alkali and other corrosion very well, and is not easy to oxidize.

⑷ Small linear expansion coefficient When working, the shape and size are stable.

⑸ The formed products are no longer processed or reground Due to the high hardness and brittleness of cemented carbide, powder metallurgy forming and sintering are no longer cut or reground. When reprocessing is required, only electrical processing such as electric spark, wire cutting, electrolytic grinding or special grinding wheel grinding can be used. Products of certain specifications usually made of cemented carbide are brazed, bonded or mechanically clamped on the tool body or mold body for use.

2. Commonly used cemented carbides are divided into three categories according to composition and performance characteristics: tungsten-cobalt, tungsten-titanium-cobalt, and tungsten-titanium-tantalum (niobium). The most widely used in production are tungsten-cobalt and tungsten-titanium-cobalt cemented carbides.

⑴ Tungsten-cobalt cemented carbide The main components are tungsten carbide (WC) and cobalt. The grade is represented by the code YG (the Chinese pinyin initials of “hard” and “cobalt”), followed by the percentage of cobalt content. For example, YG6 represents a tungsten-cobalt cemented carbide with a cobalt content of 6%, and the tungsten carbide content WC = 1-WCo = 94%.

⑵ Tungsten-titanium-cobalt cemented carbide The main components are tungsten carbide (WC), titanium carbide (TiC) and cobalt. The grade is represented by the code YT (the Chinese pinyin initials of “hard” and “titanium”), followed by the percentage of titanium carbide content. For example, YT15 represents a tungsten-titanium-cobalt cemented carbide with a titanium carbide content of WTiC = 15%.

⑶ Tungsten-titanium-tantalum (niobium) cemented carbide This type of cemented carbide is also called general cemented carbide or universal cemented carbide. Its main components are tungsten carbide (WC), titanium carbide (TiC), tantalum carbide (TaC) or niobium carbide (NbC) and cobalt. The brand is represented by the code YW (the first Chinese pinyin of the two characters “hard” and “wan”) followed by an ordinal number.

3. Advantages: Cemented carbide has high hardness, strength, wear resistance and corrosion resistance. It is known as the “industrial teeth” and is used to manufacture cutting tools, knives, cobalt tools and wear-resistant parts. It is widely used in military industry, aerospace, mechanical processing, metallurgy, oil drilling, mining tools, electronic communications, construction and other fields. With the development of downstream industries, the market demand for cemented carbide continues to increase. In addition, the future high-tech weapons and equipment manufacturing, the progress of cutting-edge science and technology, and the rapid development of nuclear energy will greatly increase the demand for cemented carbide products with high technology content and high quality stability.