What is in tungsten carbide?

What is in tungsten carbide? Tungsten carbide is a compound composed of tungsten and carbon, with a molecular formula of WC and a molecular weight of 195.85.

The following is a detailed introduction to tungsten carbide:

- Brief history of development:

Since 1893, German scientists have used tungsten trioxide and carbon to heat to high temperatures in an electric furnace to produce tungsten carbide, and tried to use its high melting point, high hardness and other characteristics to make wire drawing dies, etc., in order to replace diamond materials. However, due to the brittleness, easy cracking and low toughness of tungsten carbide, it has not been industrially applied. In the 1920s, German scientist Karl Schroter found that pure tungsten carbide could not adapt to the intense stress changes formed during the drawing process. Only by adding low-melting-point metals to WC can the blank have a certain toughness without reducing the hardness. In 1923, Schroter first proposed a patent for the use of powder metallurgy, that is, mixing tungsten carbide with a small amount of iron group metals (iron, nickel, cobalt), then pressing and molding, and sintering in hydrogen at a temperature above 1300°C to produce hardness alloys.

- Composition and characteristics of tungsten carbide:

Composition: In tungsten carbide, carbon atoms are embedded in the gaps of the tungsten metal lattice to form an interstitial solid solution without destroying the original metal lattice.

Physical properties:

Color: The color of tungsten carbide is usually gray or black, with a metallic luster.

Melting point: The melting point is relatively high, generally considered to be 2720℃~2870℃. Boiling point: 6000℃.

Density: The relative density is relatively high, about 15.63 (18℃), and the theoretical density is 15.55g/cm³.

Tensile strength:344Mpa (49893PSI).

Conductivity: It is a good conductor of electricity and heat.

Chemical properties: Tungsten carbide is insoluble in water, hydrochloric acid and sulfuric acid, but is easily soluble in a mixed acid of nitric acid and hydrofluoric acid. Pure tungsten carbide is brittle, and if a small amount of metals such as titanium and cobalt are added, the brittleness can be reduced.

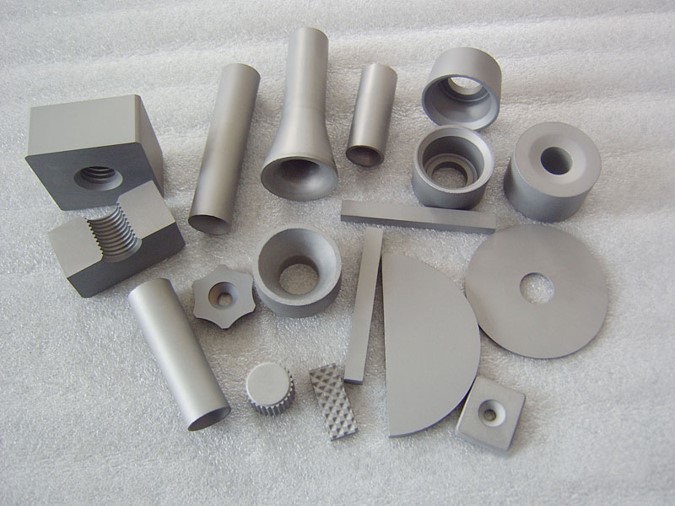

- Uses of Tungsten Carbide Tungsten carbide is a very versatile material, and its specific application areas include but are not limited to:

Cutting tools: Tungsten carbide has extremely high hardness and high temperature resistance, making it an ideal material for manufacturing cutting tools, such as knives, drills, milling cutters, etc.

Jewelry: Tungsten carbide powder can be sintered and pressed into jewelry. It has high hardness and outstanding brightness, and is deeply loved by consumers.

Abrasives: Tungsten carbide can be used as an abrasive for grinding, polishing and other processes, such as grinding wheels, sandpaper, etc.

Weapons: Tungsten carbide has extremely high hardness and can be used to manufacture weapons such as shotgun bullets and armor-piercing bullets.

Surgical instruments: Tungsten carbide is also used to manufacture surgical instruments such as scalpels and scissors due to its excellent hardness and wear resistance.

Special coatings for high-demand parts: Tungsten carbide can be used for coatings of parts that are subjected to continuous friction and must have high wear resistance, such as bearings, rotating elements, etc.

Other applications: Tungsten carbide is also widely used in engineering machinery parts, fluid distribution or flow applications (such as water jet cutting nozzles), oil and gas industries, etc. In summary, tungsten carbide plays an important role in many fields due to its excellent physical and chemical properties.

Our company is among China’s top ten cemented carbide manufacturers. Should you require cemented carbide products, please contact us.