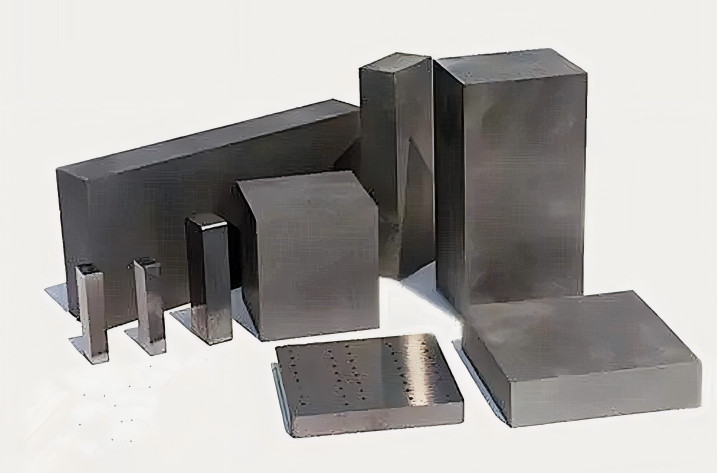

YG20 tungsten carbide material and its uses

YG20 tungsten carbide material is a WC-Co alloy, which is made of 1.6um medium-fine grain high-quality alloy powder. Its alloy composition is mainly tungsten carbide (WC), and the cobalt (Co) content is 20%. The tungsten carbide material made by powder metallurgy has good impact toughness and electrical processing properties. It is suitable for making powder pressing molds and tungsten carbide material cold heading molds and tungsten carbide material molds with complex cavities.

YG20 grade performance parameters:

| WC | Co | Grain size (μm) | Hardness(HRA) | Density(g/cm³) | TRS (N/mm²) |

| 80% | 20% | 1.6 | 85-87 | 13.4-13.8 | 2500 |

YG20 performance and use:

Mold manufacturing:

YG20 tungsten carbide material is suitable for making various high-precision molds, such as cold punching molds, cold heading molds, cold extrusion molds, etc., especially suitable for making powder pressing molds and molds with complex cavities. The life of molds and measuring tools made of cemented carbide is 20 to 150 times higher than that of alloy tool steel.

Cutting tools:

Its high hardness and wear resistance make it an ideal material for making cutting tools, such as straight cutters, circular cutters, special-shaped cutters, etc., which are widely used in metal cutting, mining and oil mining. Carbide tools have a cutting speed 4 to 7 times higher than high-speed steel, and a tool life 5 to 80 times higher. Generally, it can cut metal materials within 60HRC.

Precision parts:

YG20 tungsten carbide material is also suitable for manufacturing precision parts, such as watch parts, musical instrument springs, battery shells and toothpaste tube molds, which require materials with high wear resistance and high precision.

YG20 processing: tungsten carbide material is brittle due to its high hardness. Whether it is used, transported or processed, it is forbidden to knock or throw it. It is easy to cause safety accidents, which will cause personal injury and property loss. In order to avoid such unnecessary losses. We remind our customers to pay great attention when using tungsten carbide material.

The specific precautions are as follows:

- Precautions during cutting and grinding:

- Tungsten carbide material is prone to cracking and corner collapse under impact and excessive processing load. Cemented carbide must be firmly fixed on the workbench before processing.

- Tungsten carbide material has extremely low magnetism. Non-magnetic cemented carbide has no magnetism at all. Please do not use magnets to fix cemented carbide. Please use fixtures to fix it. Please confirm again whether the workpiece is loose before processing. If so, please fix the workpiece until it is firmly fixed.

- The processing surface of tungsten carbide material after cutting and grinding will be very smooth, and the corners are very sharp. Please pay attention to safety when carrying and using it.

- Cemented carbide is an extremely hard and brittle material. It is afraid of impact. It is strictly forbidden to hit cemented carbide with a metal hammer.

- Precautions during discharge and wire cutting:

- Tungsten carbide material has high hardness and high wear resistance. The operation process will be relatively slow during discharge and wire cutting.

- The surface of tungsten carbide material after EDM is most likely to crack and chip, so please adjust the processing procedure according to the use conditions of the product.

- Tungsten carbide material often cracks during wire-electrode cutting, so please confirm that the processed surface is free of defects after processing before proceeding to the next process.

- Precautions during welding processing:

- Please select the appropriate welding/welding processing plan according to the requirements.

- Tungsten carbide material is prone to cracks during welding. Please confirm that the processed surface is not damaged after processing before proceeding to the next process.

- When the scattered materials (welding iron) generated during welding operation adhere to the cemented carbide, the alloy is prone to cracking due to rapid heating and cooling, so please be especially careful when doing welding operations.